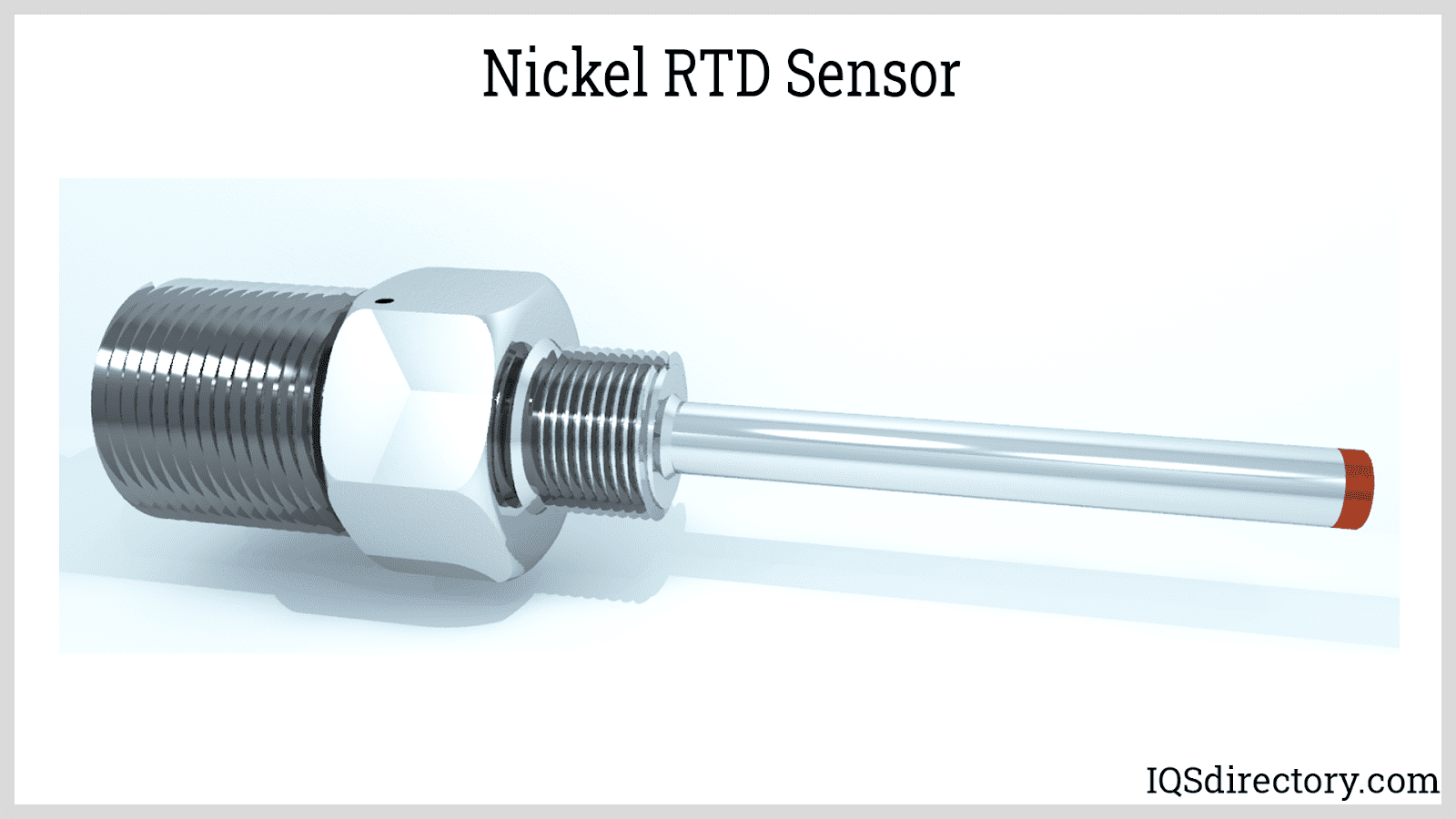

RTD devices measure temperature by proportionately changing resistance to temperature. RTD probes comprise an RTD sensing element, a housing or sheath, filler or epoxy, extension leads, and occasionally a connection or termination. There are various sensor materials available. Read More…

In business since 1972, Thermo Sensors Corporation is a leading thermocouple manufacturer of an array of many products and services.

We manufacture a full line of Thermocouples to fit your application. Temperatures from cryogenic to 4000F, and sizes ranging from needle thin to several thousand pound multipoint temperature sensors.

Kelvin Technologies is a high-quality thermocouple manufacturer, representative, and distributor for all of your electrical heating, temperature controlling, and temperature sensing requirements. Our products are engineered and manufactured in-house to address specific requirements, such as higher temperatures and more compact profiles. With over 100 years of combined experience, all of us at...

Temperature Specialists, Incorporated is a manufacturer of quality thermocouples. Temperature Specialists provide solutions for your sensing needs by building to meet your specifications. Feel free to visit their comprehensive and helpful website for full descriptions of their state-of-the-art line of quality products and services or call their experts with any questions.

Since 1971, Thermalogic has been a leading manufacturer of electronic temperature and humidity control and sensors. Here at Thermalogic we work with our clients in a partnership to build a lasting business relationship. All of our products have quick turnaround times, including custom designs, and are thoroughly tested prior to being sent out. At Thermalogic we pride ourselves on our high...

We have over 81 years of successful manufacturing experience and we offer a wide range of solutions. Our thermostats are utilized in industries including HVAC, process heating, food service, laboratory tank heating, industrial system control, and more. We have made it our mission to remain on the forefront of our industry and we work closely with our customers to ensure maximum satisfaction.

More RTD Sensor Manufacturers

As a result, RTD temperature probes and sensors can be used in various applications across numerous sectors. These temperature-sensing devices can function in harsh environments.

Working Principle

The resistance-temperature connection of the metal used in creating RTD sensors is the foundation for its function. The detector is calibrated following the measurement of the change in resistance value that results from each degree increase in temperature.

Because resistive elements are brittle, insulation is usually necessary. Therefore, the element is linked to insulator leads. PVC is used with insulators, such as molds, for temperatures under 250oC. As an outer covering, a metal alloy unreactive to temperature is utilized to house the Leads and measuring device. The temperature gradient of the sensor is the range from 0°C to a temperature margin in which the change is linear. The type of cable the sensor uses will determine this. The temperature range for platinum is up to 6600C, while the range for nickel is up to 3000C.

Types of RTD Sensors

Wire-Wound

Wire-wound RTD sensors wrap around an insulating ring or spindle. Wire-wound RTD sensors use wires made from copper, iron, and platinum. The greatest resistance-temperature relationship is provided by platinum; however, platinum wires are expensive. In addition, the expansion allowance that wire-wound elements provide makes them valuable.

Carbon Resistor

Carbon resistors are very affordable. They should only be used in applications requiring very low temperatures.

Thin Film RTD

Thin film RTDs are a light coating of platinum film deposited onto a substrate. The design etched into the RTD element creates an electrical circuit. Platinum Slim RTDs maintain accuracy across a broad temperature range and have a near-linear resistance vs. temperature relationship. As a result, the platinum RTDs benchmark is considered the European benchmark DIN/IEC 60751.

Strain-Free

Strain-free RTDs also use wire coils, but this wire is wound around over a sealed housing with inert gas rather than glass or ceramic. To allow the element to expand and contract easily in response to temperature changes, they only employ platinum wire that must be loosely wound. This element type's primary drawback is it is poorly supported and consequently prone to shock and vibration.

Considerations When Choosing RTD

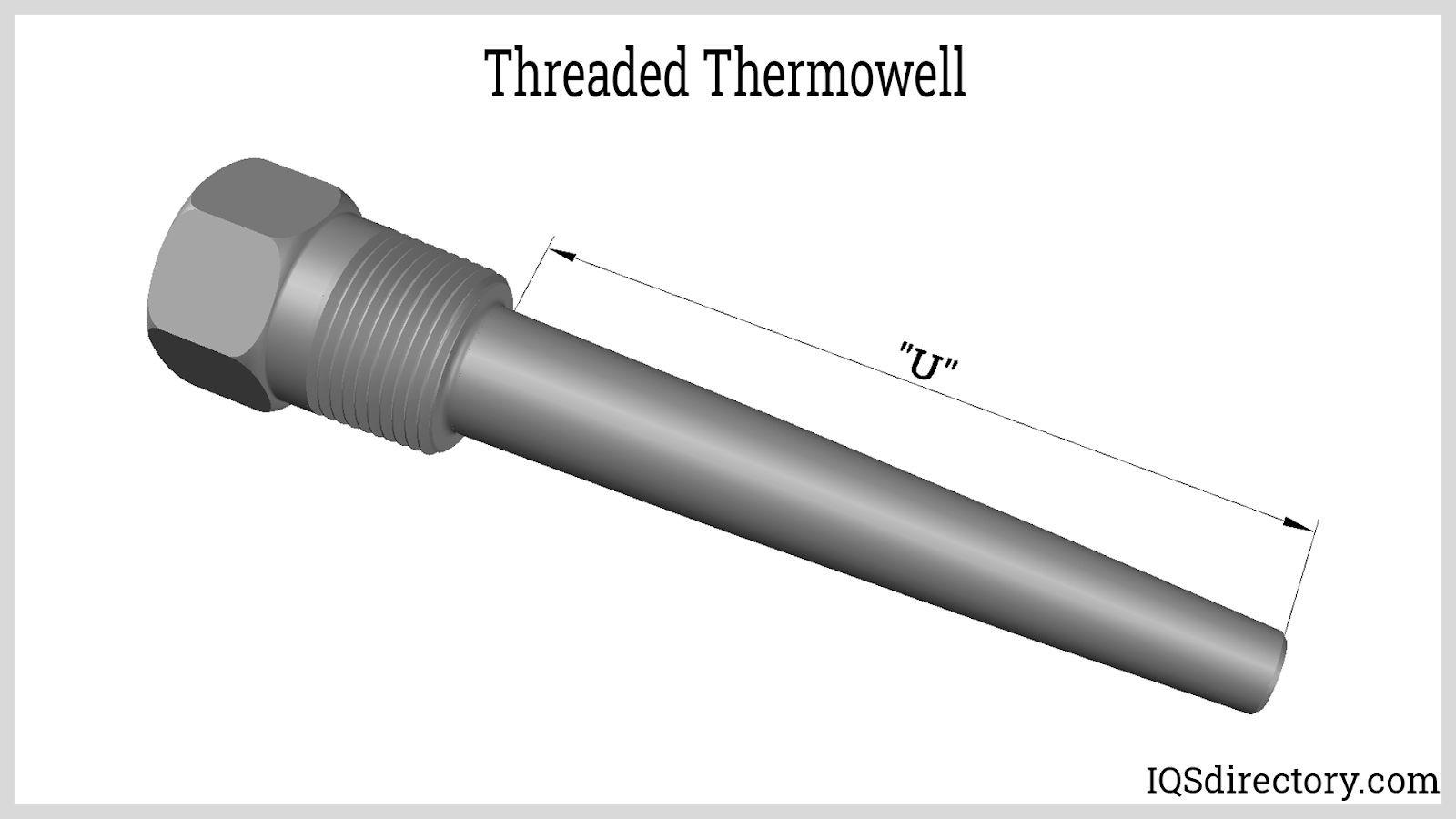

Manufacturers often offer RTD sensors attached to insulated leads if they are designed to be submerged in cold temperatures. Silicone rubber, polyvinyl chloride, or PTFE (polytetrafluoroethylene) often create these insulated lines. Additionally, producers frequently encase light sensors in shielding, unreactive metal alloy sleeves. When choosing housings or sheaths, remember they must protect the sensors from external damage (like chemical toxins, wind, rain, and other variables).

Measuring Range:

RTDs could detect temperatures of up to 1000°C. However, it’s challenging to obtain precise readings at temperatures higher than 400°C. TCs can measure up to 1700°C. The recognized rule is: for precision, use an RTD for temperatures below 850°C; for temperatures beyond 850°C, use a TC. An RTD is best for the average industrial temperature range from 200°C to 400°C.

Choosing the Proper RTD Sensor Manufacturer

To make sure you have the most productive outcome when purchasing RTD sensors from an RTD sensor manufacturer, it is important to compare at least 4 manufacturers using our RTD sensor directory. Each RTD sensor manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each RTD sensor business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple RTD sensor businesses with the same quote.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services