Temperature sensors play a crucial role in a wide range of industries and applications. These devices enable accurate measurement and monitoring of temperature, enabling precise control and efficient operations. Temperature sensors are utilized in various fields, including industrial, medical, automotive, and environmental sectors. By understanding the components, variations, and benefits of temperature sensors, we can appreciate their significance in modern technology. Read More…

In business since 1972, Thermo Sensors Corporation is a leading thermocouple manufacturer of an array of many products and services.

We manufacture a full line of Thermocouples to fit your application. Temperatures from cryogenic to 4000F, and sizes ranging from needle thin to several thousand pound multipoint temperature sensors.

Kelvin Technologies is a high-quality thermocouple manufacturer, representative, and distributor for all of your electrical heating, temperature controlling, and temperature sensing requirements. Our products are engineered and manufactured in-house to address specific requirements, such as higher temperatures and more compact profiles. With over 100 years of combined experience, all of us at...

Temperature Specialists, Incorporated is a manufacturer of quality thermocouples. Temperature Specialists provide solutions for your sensing needs by building to meet your specifications. Feel free to visit their comprehensive and helpful website for full descriptions of their state-of-the-art line of quality products and services or call their experts with any questions.

Since 1971, Thermalogic has been a leading manufacturer of electronic temperature and humidity control and sensors. Here at Thermalogic we work with our clients in a partnership to build a lasting business relationship. All of our products have quick turnaround times, including custom designs, and are thoroughly tested prior to being sent out. At Thermalogic we pride ourselves on our high...

We have over 81 years of successful manufacturing experience and we offer a wide range of solutions. Our thermostats are utilized in industries including HVAC, process heating, food service, laboratory tank heating, industrial system control, and more. We have made it our mission to remain on the forefront of our industry and we work closely with our customers to ensure maximum satisfaction.

More Temperature Sensor Manufacturers

Components and Operation of Temperature Sensors

Temperature sensors typically consist of three main components: a sensing element, a signal processing unit, and an output interface. The sensing element detects temperature changes and converts them into electrical signals. The signal processing unit amplifies and filters the electrical signals to improve accuracy and eliminate noise. Finally, the output interface provides the temperature readings in a usable form, such as analog voltage, digital data, or wireless communication. By combining these components, temperature sensors enable precise and reliable temperature measurement.

Variations in Temperature Sensor Design

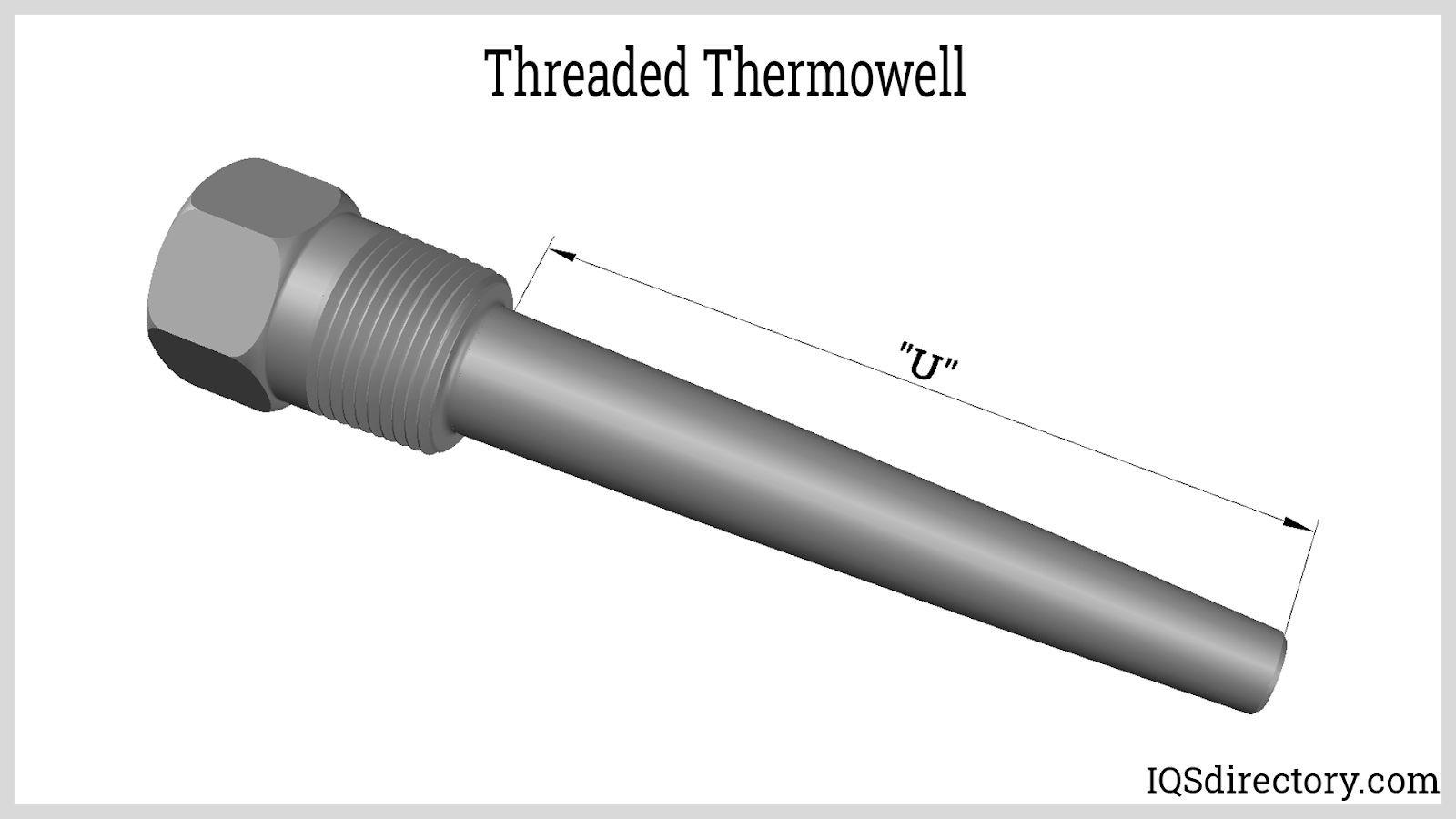

Temperature sensors come in various types, each with its unique design and sensing mechanism. Thermocouples are based on the principle of thermoelectric effect, utilizing the voltage generated at the junction of two dissimilar metals to measure temperature. Resistance temperature detectors (RTDs) rely on the change in electrical resistance of metals, like platinum, with temperature variations. Thermistors, on the other hand, utilize the resistance change of semiconductor materials. Infrared (IR) temperature sensors, meanwhile, measure temperature by detecting infrared radiation emitted by objects. Finally, semiconductor temperature sensors exploit the temperature-dependent characteristics of semiconductors. Each variation has specific advantages and applications, such as thermocouples for high-temperature environments, RTDs for precise measurements, thermistors for cost-effective solutions, IR sensors for non-contact measurements, and semiconductor sensors for miniaturized applications.

Considerations Regarding Temperature Sensors

While temperature sensors offer immense benefits, there are some considerations to account for. Environmental considerations, such as extreme temperatures or corrosive atmospheres, can affect sensor performance and longevity. Accuracy and calibration issues may arise due to drift or aging of the sensing element. Interference and noise can also introduce errors in temperature measurements. It is crucial to understand these factors and choose the appropriate sensor for the specific application to mitigate these concerns effectively.

Manufacturers Address These Considerations

Manufacturers have taken several steps to overcome these considerations associated with temperature sensors. They have improved the accuracy and calibration processes to ensure reliable temperature readings. Advanced signal processing techniques, including filtering and noise reduction algorithms, have helped eliminate interference and improve measurement accuracy. Additionally, manufacturers have developed rugged and robust temperature sensors capable of withstanding harsh environmental conditions. Their creation and integration of advanced filters and shielding mechanisms have further advanced sensor performance and reduced noise and interference.

Benefits of Temperature Sensors

Temperature sensors offer numerous benefits across various industries. Their precision and accuracy enable precise control of processes and systems. Temperature sensors can cover a wide temperature range, making them suitable for diverse applications. Non-contact temperature measurement provided by infrared sensors eliminates the need for physical contact and is ideal for delicate or inaccessible objects. Temperature sensors also boast compact size and ease of integration into existing systems. With their cost-effectiveness and energy efficiency, these sensors contribute to optimized operations and reduced resource consumption.

Applications of Temperature Sensors

Temperature sensors find extensive use in industrial applications, including HVAC systems for optimal temperature control, manufacturing and process control to ensure quality and efficiency, and food processing and storage to maintain safety standards. In the medical field, meanwhile, temperature sensors are crucial for patient monitoring, laboratory equipment, and thermal imaging for diagnostics. Automotive applications, additionally, rely on temperature sensors for engine temperature monitoring, climate control systems, and battery temperature management. Environmental monitoring also benefits from temperature sensors in weather stations, greenhouses and agriculture for optimal plant growth, and energy efficiency optimization.

Temperature Sensors and the Future

Looking ahead, future developments in temperature sensing technology hold promising prospects. Advancements in materials science and miniaturization techniques may lead to the development of even more compact and highly sensitive temperature sensors. Integration with IoT (Internet of Things) platforms and wireless connectivity may enable seamless data acquisition and remote monitoring. Furthermore, the incorporation of artificial intelligence and machine learning algorithms may enhance the accuracy and predictive capabilities of temperature sensors, facilitating proactive maintenance and system optimization.

Choosing the Proper Temperature Sensor Supplier

To ensure you have the most positive outcome when purchasing temperature sensors from a temperature sensor supplier, it is important to compare several companies using our directory of temperature sensor suppliers. Each temperature sensor supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each temperature sensor business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple temperature sensor companies with the same form.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services